Introducing Formech's New Guide to 3D Printing for Vacuum Forming

Introducing Formech's New Guide to 3D Printing for Vacuum Forming

Which materials to use and which to avoid

Which materials to use and which to avoid

The worlds of 3D printing and vacuum forming are a perfect match. Additive manufacturing offers incredible speed, design freedom, and cost-effectiveness, making it a powerful alternative to traditional toolmaking methods like CNC-machining MDF, model board, or casting epoxy resins.

3D Printing Questions

As interest in this combined technology has grown, so have the questions. We regularly receive enquiries from customers excited to use their 3D printers to create tooling, but who are unsure of the best practices. Which filament should I use? What print settings are optimal? How do I prepare my printed tool to ensure a perfect finish?

While the potential is huge, the process has pitfalls. A poorly chosen material or incorrect print setting can lead to a failed tool that deforms, cracks, or even melts under the heat and pressure of the vacuum forming process.

New Guide from Formech

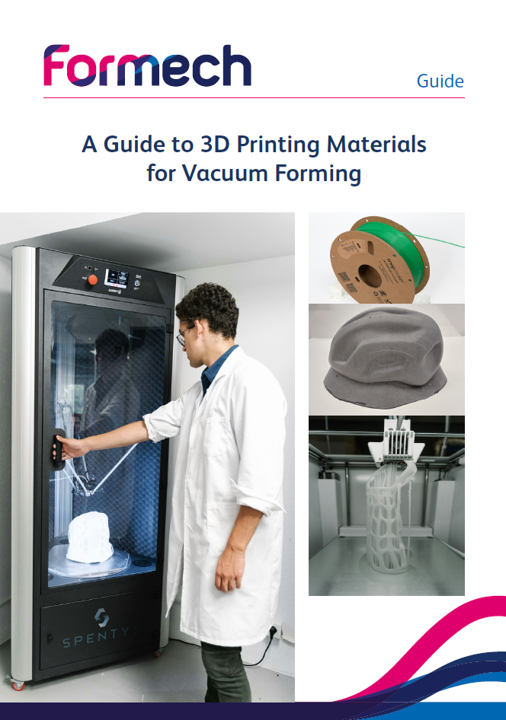

To help you navigate this exciting field with confidence, we are thrilled to announce our new Guide to 3D Printing Materials for Vacuum Forming.

Clear, Practical Guidance You Can Trust

This guide has been written by our team of experts to provide quick, easy-to-understand guidance for anyone using, or considering using, 3D printed tools for their vacuum forming applications.

Inside, you'll find essential information, including:

- Description of the material technology

- List of 3D printing materials

- The typical properties of the materials

- Notes on their suitability for vacuum forming

Whether you are a product designer creating rapid prototypes, an engineer testing functional parts, or an educator introducing students to modern manufacturing techniques, this guide is for you.

Download now

Ready to get started? Download your free guide today and start making incredible vacuum-formed parts with your 3D printed tools!